|

By Richard Seireeni |

|

|

|

For A Piece of The Electric Pie. by Richard Seireeni, Brand Architect August 6, 2008 |

||||

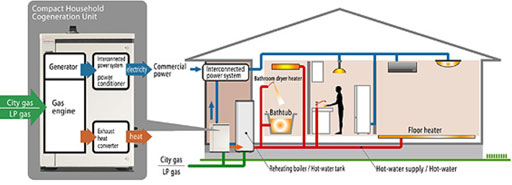

I've just come back from visiting a display in the fashionable Shinjuku district sponsored by Tokyo Gas. It's sweltering here, but they are showing off a very cool idea. The city's gas company is promoting two different systems that use natural gas to create electricity for the home. One system, called ECOWILL, uses a gas-powered heat engine to produce electricity with excess heat used to warm water for the sinks, bath and radiant floor heating. The second system, called LIFUEL, uses gas to power a hydrogen fuel cell that produces electricity. The waste heat from this system is also used to heat water. The former was introduced last year, while the latter was first field tested in 2002 and launched in a limited pilot program in 2005. So after years of testing, Tokyo Gas is ramping up. Both systems are being aggressively marketed under the "My Home Hatsuden" program, meaning 'my home generator'. In addition, Honda and other automakers are experimenting with hydrogen production systems in the home to power the family car. The vision is to use clean burning natural gas to provide household electricity, hot water and heating as well as fuel for the car — all with one in-home system. If the gas companies get their way, young Japanese will live in a very different world where there will be options to the electric utility and the corner gas station. According to a post on the Pink Tentacle blog last year, "Tokyo Gas was initially focused on developing household fuel cells. However, after Tokyo Electric Power Company (TEPCO) stepped up efforts in its push for all-electric housing, Tokyo Gas decided to counter by focusing on ECOWILL until fuel cells achieve full-scale popularization. Tokyo Gas plans to increase the installation of ECOWILL and LIFUEL (systems) in general households from 200 (pilot program) units in 2005 to a cumulative total of 43,000 units (by) 2010. Norio Ichino, President of Tokyo Gas, expects "My Home Hatsuden" to play a key role in their business in 4 to 5 years." The systems, which cost about 870,000 yen (US$8,000), are backed by the Japanese government with substantial subsidies. However, the net savings over traditional electricity to a family of four is modest. LIFUEL can save a family about 60,000 yen (US$550) per year in heating and lighting costs. ECOWILL saves about 27,000 yen (US$250) per year.

Conceptual diagram of the Honda cogeneration system. This leads to the more important eco-claim that much of the electricity made by electric power plants is lost in transmission. (I almost wrote 'lost in translation', but that's another experience I go through on trips here.) Only about 37% actually gets to the point of use. That's because the electrical grid is built for peak usage and cannot store the excess electricity. Added to this is the lost of energy over long distance transmission lines. With natural gas, very little product is lost through the pipelines where it is then efficiently converted into electrical energy and heated water at the site with only a 22% loss in efficiency. Tokyo Gas goes on to detail the complex calculations of carbon footprint on their website. According to the company press release, they claim that their gas to electric system, "reduces emissions of carbon dioxide by 29% and primary energy consumption by about 19%." Manufacturing partners for the ECOWILL program are Honda, Noriz and Chofu. For the LIFUEL polymer electrolyte fuel cell system, Tokyo Gas partners are Ebara Ballard Corporation and Matsushita Electric Industrial Company (aka Panasonic) although there are other PEFC makers in Japan. A more advanced system called solid oxide fuel cell (SOFC) is under development by Kyocera. The program is also being deployed by other Japanese gas companies including the Osaka Gas Group in the Kansai area. Companies in the UK and Germany are also experimenting. According to the engineering abstract, Micro Cogeneration, this is an important example of the movement toward decentralized energy systems. So even as Tokyo Gas sets its sights on the home electricity market, it is also investing in the hydrogen fuel cell automotive market. In May of 2003, Tokyo Gas and Nippon Sanso Corporation opened the first Senju hydrogen station at their Arakawa-ku facility, near Tokyo. The raw material for the hydrogen production is liquefied petroleum gas. As in the home co-generation program, they claim that hydrogen auto fuel made from LPG will be more earth friendly than other alternatives. Nevertheless, the prospect of making hydrogen for the family car at home holds the promise of eliminating one of the major obstacles to hydrogen cars, which is a national network of hydrogen refueling stations. By making heat, hot water, electricity and car fuel at home, we're beginning to see a synergistic vision of the future. © Rick Seireeni, Brand Architect and President The Brand Architect Group is a strategic brand consultancy with offices in Los Angeles, Tokyo and Shanghai. Project specialties include retail, food service, banking and real estate development.

|

Tokyo Gas exhibit displaying co-generation systems that make electricity and hot water at home from gas.

The Senju hydrogen production and refueling station under administration of Tokyo Gas as part of the Japan Hydrogen Fuel Cell program.

Tokyo Gas and Mitsubishi Heavy Industries have come up with a much smaller hydrogen pump that should make it simpler to fit out normal petrol stations. Articles by Richard Seireeni: |

![]()